Assembling sheets and layers during the diaper manufacturing process involves several steps. The bond between each part must be flawless and any interference to the adhesive on the product kept to a minimum.

A common myth amongst manufacturers is that a strong, long-lasting bond means that it is necessary to use higher amounts of adhesive. This is false. By using specific patterns engineered to have higher adherence and locating the pattern in certain key spots, the use of adhesive can be decreased, while the strength of the bond increases. In other words, it’s not the amount of hot melt you use, but how you apply it.

Tests at diaper manufacturer facilities have proven that a 50% reduction of adhesive usage is possible by switching from standard spray hot melt dispensing applications to multi-spray adhesive patterns. During spray applications, the surface is covered from side to side with a swirl pattern. With the multi-spray option, the same surface is instead covered by 3 parallel mini-swirls. This application creates a pattern with a high number of adhesive swirl intersections to give additional strength using lower amounts of adhesive.

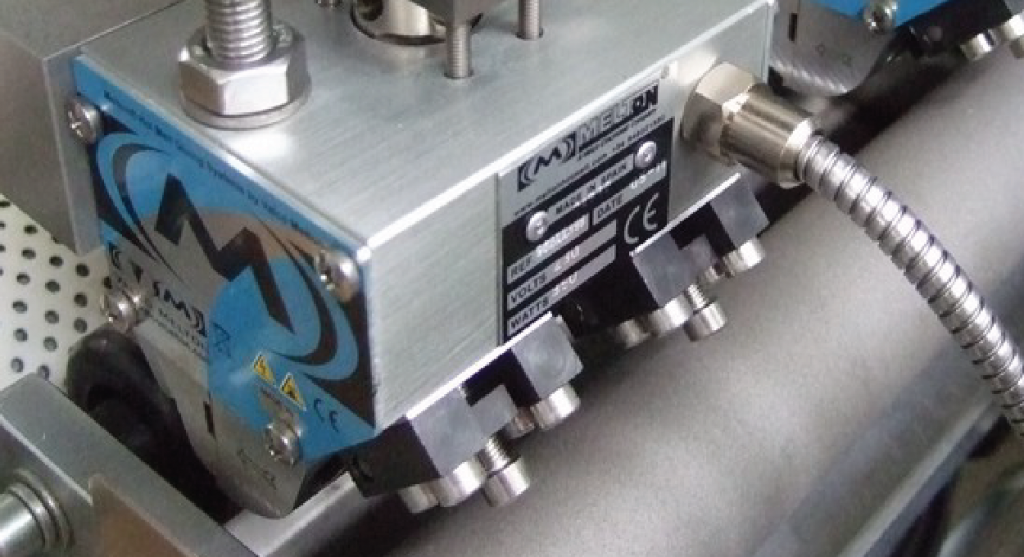

Aside from adhesive usage reduction, further savings can be attained by using hot melt modules with removable “insert nozzle” technology. This innovative concept permits easier cleaning and pattern configuration processes. The tip of the nozzle features 3 small inserts that provide a highly accurate mini-swirl pattern. A special air output design avoids nozzle clogging while reducing costly downtime.

Additionally, inserts like Valco Melton’s NWV BAT22 Inserts can be easily extracted and replaced, facilitating and reducing the time spent on cleaning and maintenance operations. Inserts can be combined with blanks for additional pattern configurations with minimal spare parts investment and work-change times.

Spare parts inventory can also be reduced as an effect of this hot melt technology. If any malfunction occurs, there is no need to replace the whole nozzle, just the defective insert. By only replacing the inserts, some of the users of our multi-pattern modules with insert-nozzle technology have experienced proven savings of up to 40-60% in their spare parts expenditure.

If you are interested in a deeper technical analysis, here is a white paper detailing the savings a customer achieved at their facility by replacing their swirl spray hot melt systems with multi-spray hot melt technologies.