This post was edited from a previous version posted August 31st, 2016.

For bookbinding equipment like perfect binder machines, having an energy-efficient hot melt dispensing system that can quickly meet full production melt rates is critical.

Conventional pot filling systems are commonly used with bookbinding applications. The melt unit’s pump size and control can be configured as required for specific application needs and are equipped with precision controls to ensure stable temperature and promote adhesive pot life. However, with adhesive sitting idly in the chamber, glue pots experience adhesive degradation, charring, and maintenance problems caused by plugged nozzles.

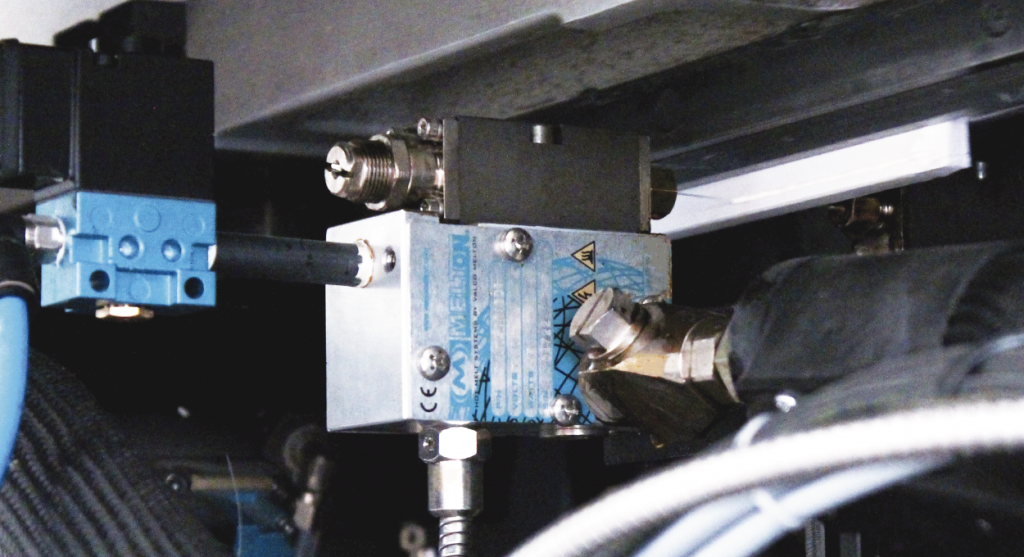

Technological advances have increased the number of available adhesive dispensing options for side gluing applications, specifically, high-speed hot melt glue guns. Not only is this option for bookbinding more cost-effective than purchasing an entirely new machine to increase efficiency, but hot glue guns support glue savings, provide a cleaner cut-off and decrease the need for maintenance.

Glue Savings

Some high-speed glue guns can reach up to 3000 cycles per minute and can be set to run on stitch mode to apply minimal adhesive beads with virtually no stringing. These types of effective extrusion systems offer highly accurate bead placement and more uniform glue volume, which translates to a reduction of up to 75% in adhesive usage.

Cleaner Cut

There’s virtually no stringing with high-speed hot melt guns, which translates into a higher quality end product. Normally, when stringing occurs, it forces operators to cut the edges where there is an excess of adhesive. With a cleaner cut-off, this requirement is eliminated.

Less Maintenance

When stringing occurs, adhesive can get into the bookbinding equipment and interfere with proper functioning. The cleaner cut-off offered by high-speed hot melt guns prevents this from happening, resulting in less maintenance. Additionally, all-electric high-speed hot melt guns contain less dynamic seals, preventing the constant replacement of spare parts and diminishing performance commonly associated with pneumatic valves.

From increased glue savings and reduced maintenance to a more accurate adhesive application, when combined, high-speed hot melt glue guns deliver a higher quality book and offer a more efficient and effective means to upgrade your perfect binder.

Questions about which option is the best for your requirements? Valco Melton’s expert sales engineer team can help you to determine the right book-binding solution for your operation. You can reach out to them directly at any time, here.