Today, the corrugated box industry is very competitive. Not only do you need to deliver corrugated boxes in record times at unbeatable prices, but with the various technologies available, the standard requirements for corrugated box manufacturers have been set extremely high. You are now expected to deliver flawless, 100% defect-free boxes. In an effort to help you manufacture boxes at the highest possible level, we have gathered together a few important points, learned from over 60 years in the industry.

- Keep it clean! I’m sure many of you are tired of hearing those three words. But, as many others will tell you, it wouldn’t need to be said, if everyone made sure to do it. If you are working with an older glue pot and wheels, you know they tend to generate a little glue slinging. This can affect the quality of the glue joint and create stickers where boxes in the bundle will stick together. Gluepot and wheels can also create adhesive contamination with dust and debris. Additionally, the metered amount of adhesive is hard to maintain to ensure a proper bond. As for adhesive applicators, although they are the cleanest choice, it is important to check them regularly to avoid possible nozzle or applicator clogging.

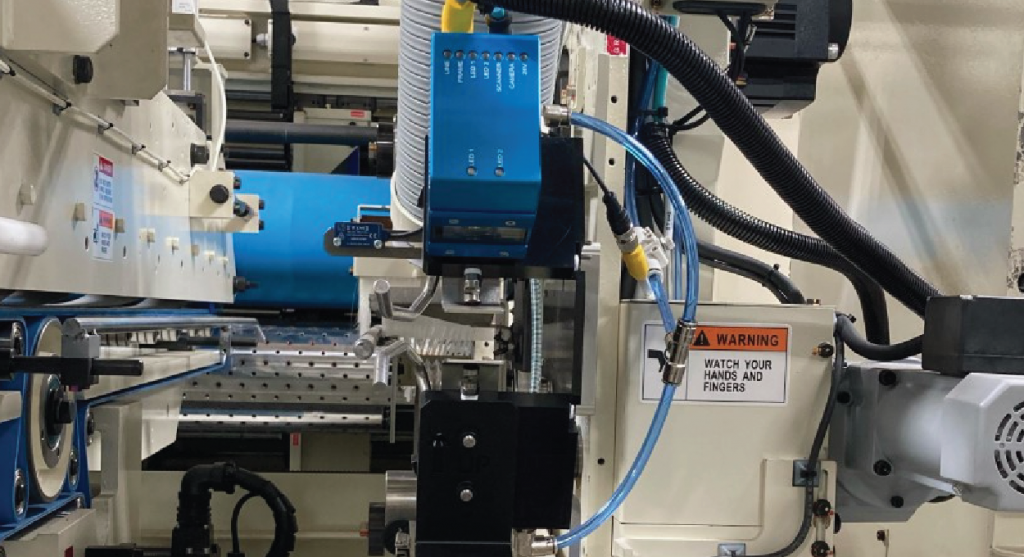

- Minimize any possibility of human error. This may seem impossible to some, but it can be done. When working with different sized board panels and speed requirements in the corrugated box industry, it is necessary for the operator to constantly adjust the pattern length and placement in order to keep a consistent and high-quality adhesive application. This is a time-consuming task; any distraction can cause a misadjustment that will result in product loss. It is now possible to upgrade your adhesive application system to a gluing station with automated pattern changes or auto-glue, which ensures a proper glue-lap joint regardless of the length of the tab or panel.

- Ensure that the board has been glued, folded and printed properly. These days this is possible by incorporating squality assurance vision inspection systems into your process. Quality assurance has 3 components: identify the non-conforming product, remove it from the production line, and monitor the lines’ statistics to hold plant operations accountable. All 3 are possible in ways not imagined five years ago in the corrugated box manufacturing industry, with vision-based quality assurance. Snapshots of defective products are saved and cataloged. Machine performance can be monitored remotely and statistically analyzed. The same statistics enable managers to be aware of developments on converting lines as they occur and to take corrective action in a timely fashion.

- Scrap can blotch your reputation. For a flawless result, incorporate a scrap or tab removal system to prevent hanging scrap that has not been properly cut after being folded into the box.

5. Get rid of defective boxes before they make it onto your delivery truck. Bundle ejection systems are used in conjunction with a quality assurance system to guarantee that the defective boards are removed from manufacturing and not shipped to the customer. As the second major component of a Quality Assurance System in paper converting, removing defective product from the line automatically is unparalleled in regards to effectiveness. All other options rely on operators to sort product or catch errors and take them out of the stream. Automatic ejection takes care of the removal without interrupting production.

By implementing these tips into your manufacturing process today, you will begin seeing its direct impact on the quality of your corrugated boxes. If you are interested in hearing more about any of these topics, please let me know!

To be notified when a new tip or story has been added to our blog, receive updates automatically. It’s easy! Just add this blog’s feed to a feedreader of your choice by selecting the orange RSS icon at the top of this screen. If this sounds like brain science to you (and that is not your specialty), it’s not! I would be happy to help you learn how to do this. It is a great way to stay up on news across a range of sources from one location, saving you valuable time. Just let me know! – Laura Magee, Global Marketing Director