About Potential Manufacturing Improvements, Updates & Getting Lean in the New Year

Are rising Kraft® paper and Kraft paperboard costs eliminating profits in your box manufacturing company? Whether you work as a corrugated box manufacturer in Newfoundland, India, California or anywhere else on the globe, there are great opportunities to increase corrugated manufacturing profits by improving your facility operations.

Corrugated Manufacturing Improvements

Start improvements where there are problems. Do you have dated or old machinery running that makes it impossible to run faster, with less waste and without manufacturing interruptions? Or are you looking to solve problems with the two most common corrugated box defects:

- Improperly glued or unglued box defects

- Not square boxes or manufacturer’s gap not up to specification requirements

There are no bad improvements, but in manufacturing, the best improvements show a quick return on investment (ROI).

Updating Old Systems to Save Time & Resources

No matter the quality of the equipment, when your plant operates with dated machinery things can get off track. Maybe your old equipment is slowing plant operations and making it hard to compete with other firms. Or maybe finding replacement parts for obsolete equipment has led to lengthy line shutdowns that cost you money.

When upgrading improves your ROI, it makes the decision easy. For instance, upgrading dated equipment such as older extrusion systems, glue stations or even old glue wheels will have a dramatic effect. Not only will updating those types of systems reduce system breakdowns and eliminate frantic searches for obsolete spare parts, but it will also increase manufacturing profits. Updates do not have to be big to be valuable. Even something like updating your obsolete glue system pattern controls and adhesive stations can easily help you apply proper amounts of glue and cut down on wasted boards and adhesive costs to improve your bottom line.

Improving Efficiency Through Automated Manufacturing Inspection Systems

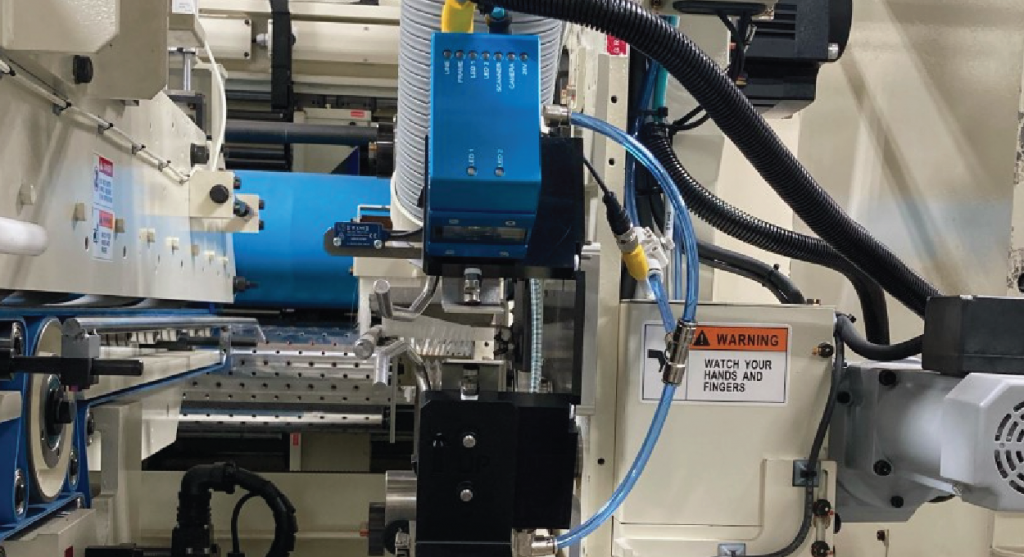

New technology purchases should not only be about updating what you have, but new technology should also be about making your operations more efficient. An automated manufacturing inspection system could be a huge advance in streamlining your manufacturing operations. Systems such as Valco Melton’s ClearVision bring high-speed automated quality assurance processes that will improve your average completion rate and average throughput for corrugated box manufacturing.

Automated manufacturing inspection cameras can find defects ranging from improperly glued or not square boxes as well as other defects such as print variation or measurement checks while operating at full manufacturing line speeds. These automated quality control inspection tools can also be combined with automatic bundle ejection systems to pull out corrugated box defects while operating at full speed. Plus, the only thing as quick as installing a quality assurance tool such ClearVision system is the speed at which it shows a return on investment.

Stay Calibrated: Tune-Ups & Preventative Maintenance Can Help

When you put the time, effort and money to get your operations running without a hitch it does not make sense to lose that operational efficiency as normal maintenance issues arise. It can happen slowly over the course of months and years, but every small imbalance adds up and in time you will find your system is running slower and producing more defects than it used to. When you have the staff expertise and time, putting regular tune-up and equipment inspection time into your teams’ schedules can make all the difference. However, if your teams are already booked wall to wall or if you do not have the expertise to calibrate the equipment yourself – A preventative maintenance contract for regular equipment tune-ups and service plans can prevent break-downs, maintain peak levels of manufacturing efficiency and save you money over the course of a year. Evaluate your manufacturing operations, staff expertise and available hours to see if a tune-up and service plan would be good for your manufacturing equipment and line operations to increase manufacturing profits in 2019.

Improvements, Updates & Maximizing Efficiency

Maximizing the efficiency of your corrugated manufacturing business is about making smart improvements, choosing system updates or upgrades with a good ROI and about maintaining lean operations. But more than that, it is about the bottom line and long-term profitability of your corrugated manufacturing business.

Learn more about Valco Melton’s ClearVision System and how automated manufacturing inspection tools can help you deliver the Perfect Box to your end-user every time.

Ask an Expert about how software updates or preventative maintenance plans can increase your company profits.

Would you like to read more? Here is another topic you may find appealing, Box Manufacturing Issues & Solutions.