If you’re in the market of using pressure-sensitive adhesive with a deferred-use seal machine for corrugated box products, folding cartons, or envelopes with conventional paper converting machinery, it’s important to consider production speeds and volume when making the decision between a double-sided transfer tape applicator system or a system that applies pressure-sensitive adhesive followed by a covering release liner. Both double-sided transfer tape and pressure-sensitive adhesive sealing systems with release liner get the job done, but which method completes the task most efficiently while giving the highest quality product and the most cost-effective solution? I’d say it depends largely on a few things.

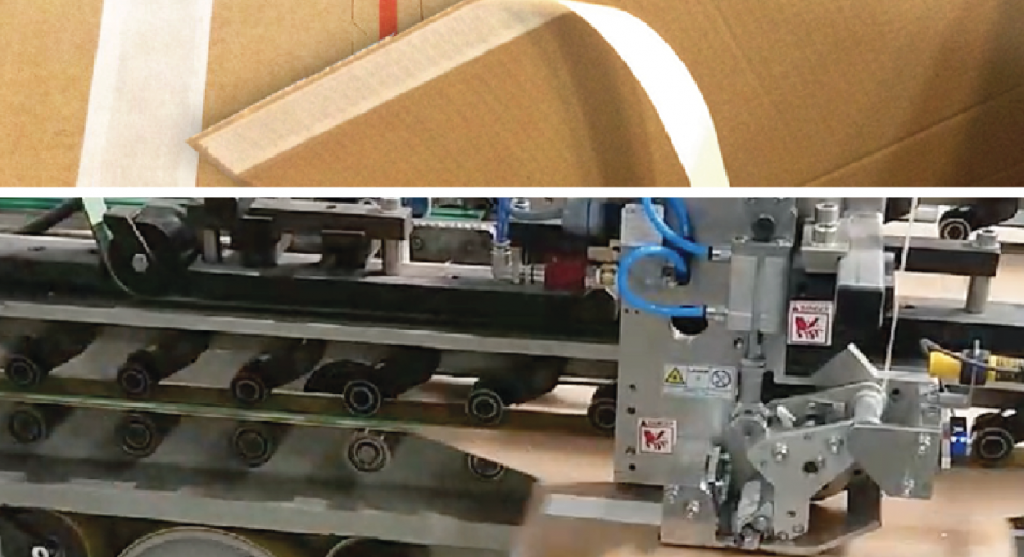

The pressure-sensitive adhesive applied in ribbon, bead, or spray form during the converting process on the converting machine is deposited evenly onto the substrate surface. This process produces a much stronger bond than adhesive transfer tape systems. The release liner overlay can be customized for length and width coverage to offset the adhesive pattern thus providing the easy peel and seal feature that is not possible with transfer tape.

By eliminating the need for excessive transfer tape roll changes, production significantly increases, while simultaneously decreasing downtime and reducing material costs by 40% or more. The cost of buying bulk adhesive and bulk silicone paper is far less than the cost of transfer tape and is easier to inventory and store.

If you are looking for a more efficient process, a stronger bond, to reduce material cost, increase production, and decrease downtime, I’d suggest using the Valco Melton SealTak® deferred-use sealing equipment method. Just do the math and decide what makes the most sense for your company.